Phone: 1-888-323-5131 (toll free US only)

Phone: 1-215-526-2180 (worldwide)

Fax: 215-526-2191

Email: info@verigenics.com

Expansion Progress

| NEWAGE®/ADVANTAPURE® MANUFACTURING EXPANSION VIDEO |

|

If you have questions about our plans and progress, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| SETTING UP EXTRUSION EQUIPMENT IN THE NEW CLEAN ROOMS AT OUR WARRINGTON, PA OPERATIONS November 22, 2021 |

| WARRINGTON FACILITY — Tubing extrusion equipment for our AdvantaSil® silicone tubing and reinforced hose and for AdvantaFlex® TPE tubing is being assembled in three of the seven new clean room manufacturing suites at our Warrington facility. The remaining four clean rooms are undergoing final HVAC and electrical work and will soon be tested for air quality.

AdvantaSil APST platinum-cured silicone tubing will be manufactured on this equipment shown above. Machinery includes not only the extruder but laser monitors for tubing dimensions, coilers, and packaging equipment.

This new mill will be used to process raw silicone prior to tubing production.

The application of braid material for our AdvantaSil APSH reinforced silicone hose will take place in this clean room.

This additional silicone tubing manufacturing room will be ready for air quality tests soon.

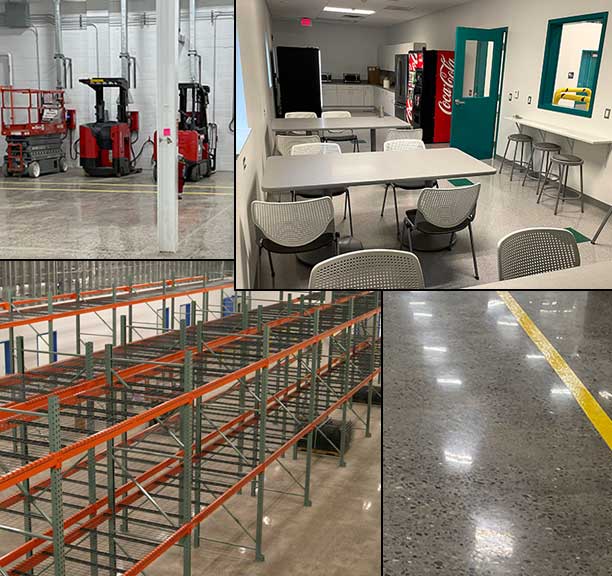

Other portions of the facility, such as break rooms and storage areas, have been constructed and are ready for team members and products.

If you have questions about our plans and progress, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| EXTRUSION EQUIPMENT IS MOVED INTO CLEAN ROOMS AT OUR WARRINGTON, PA BUILDING October 29, 2021 |

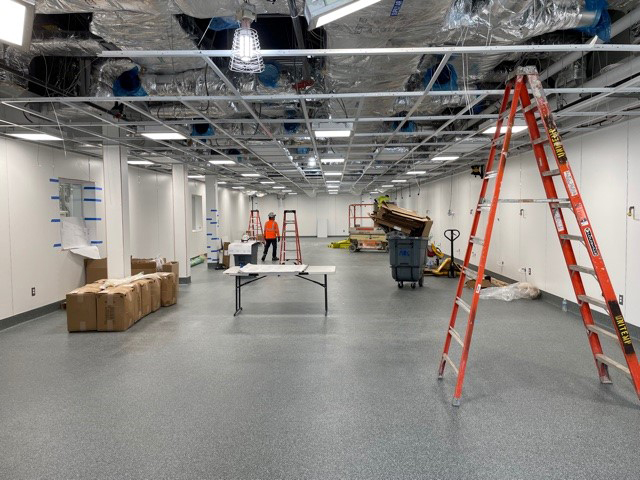

| WARRINGTON FACILITY — Air quality testing for "as built" conditions in several of the new clean rooms at our Warrington Operations expansion is complete, and extrusion equipment has been moved into the rooms.

A rigging company was hired to move extruders and other heavy machinery into the finished clean rooms. Here, an experienced rigger watches for clearance at the top of this extruder component. All extrusion machinery was made in the U.S.

The equipment is carefully positioned to align with installation marks on the floor.

Other extrusion line pieces are set in place in this room that will be used to manufacture AdvantaFlex® weldable and sealable TPE tubing.

Another clean room and its machinery are designated for AdvantaSil® platinum-cured silicone tubing. An adjacent room will be used to apply braid material for manufacturing our APSH braid-reinforced silicone hose.

Other clean rooms at the facility have HVAC and electrical tasks wrapping up and will soon be air quality tested.

If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| SEVERAL CLEAN ROOMS ARE READY FOR TESTING AT OUR WARRINGTON, PA BUILDING October 15, 2021 |

| WARRINGTON FACILITY — Permanent doors and windows are in place, and testing of the finished clean rooms at our expansion site can soon begin.

The room pictured above is where AdvantaFlex® weldable and sealable TPE tubing will be manufactured.

This space is designated for AdvantaSil® platinum-cured silicone tubing production.

Other clean rooms are rapidly nearing completion. The orange glow seen through some of the windows indicates the thick, orange, protective plastic used to cover new clean room flooring. The color reflects off the white walls and ceilings.

Extrusion equipment – all made in the United States – is being stored in the warehouse area of the building until installation time.

If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| DOOR AND WINDOW INSTALLATIONS ADVANCE PREPARATIONS FOR EQUIPMENT INSTALLATION AT OUR WARRINGTON, PA OPERATIONS October 01, 2021 |

| WARRINGTON FACILITY — Most clean rooms now have exterior, as well as interior, walls. Floors are being completed, and windows have been installed between clean rooms. Doors – both high speed and personnel doors – have arrived and are being set into place.

Here in one of the main hallways, outer walls are sheathed and a few personnel doors are seen.

High speed doors will allow for a quick transfer of materials into the clean rooms with the least amount of air and particulate disturbance.

Even ladders have to wear protective coverings – booties – on this new clean room floor.

A temporary door covering allows technicians to perform rough balancing, a process involving air flow and pressure, in this room that will house extrusion equipment for AdvantaFlex® TPE tubing.

We're now just a week away from setting up tubing extruders and moving in support equipment such as packaging areas and inspection tables. If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| CLOSER TO SETTING UP TUBING EXTRUSION EQUIPMENT AT OUR WARRINGTON, PA OPERATIONS September 17, 2021 |

| WARRINGTON FACILITY — Most of the clean rooms at our Warrington facility now have interior walls, and many have glass in the windows. More flooring is being installed as well. Ceilings and lights are up, and HVAC hook-ups are in process.

Above, multiple rooms are now sheathed in clean room wall material.

Clean room after clean room is seen through these window openings.

Clean room floors are sanded as one of the final steps in the finishing process.

Heating, ventilation, and air conditioning connections are wrapping up in this room.

Pictured here are some of the mills, hose reels, and material handling equipment that will be needed. The equipment is in storage in the building's warehouse area.

Our contractor is moving swiftly, and we anticipate moving extrusion equipment into the finished clean rooms within the next few weeks. If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| CLEAN ROOM SUITE CONSTRUCTION PROGRESSES AT OUR WARRINGTON, PA FACILITY September 10, 2021 |

| WARRINGTON FACILITY — Construction of clean rooms, destined to be tubing extrusion suites, is moving forward. Some rooms have floors ready and are awaiting HVAC and electrical connections and ceilings; others are in the midst of wall construction, and still others are in the wall stud phase. Additional spaces – offices, break rooms and mechanical rooms – are all in the making.

Above, steel parts are trimmed for exact fit into one of the future clean rooms.

In this room, heavy-duty plastic temporarily protects the finished floor while utility connections are made and ceilings are installed.

A worker takes measurements before cutting a new piece of clean room wall covering.

In addition to clean rooms, several offices, storage rooms, and, of course, restrooms are being built.

Supplies such as cabinets, tables and trash cans are stored in the warehouse area, ready to be put to use.

If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| OUR CLEAN ROOM EXPANSION AT SOUTHAMPTON IS COMPLETE September 07, 2021 |

| SOUTHAMPTON FACILITY — We're happy to announce that we have finished the 3,100-square-foot clean room expansion at our headquarters.

After planning and hiring a clean room contractor, demolition work started in April and was followed by new concrete footings for support beams, a mezzanine for utilities, ducts for air transfer functions, and electric service lines. Work continued with vents and additional ductwork, clean room wall construction, flooring, lighting, and the ceiling. Within two days of air quality testing, mold presses were moved into the space, set up, and calibrated. Our production capacity for Single-Use tubing assemblies has now increased, as team members have more presses, preparation room, manufacturing space, and square feet in which to construct and inspect the many tubing assemblies on order, including large complex systems with bags, filters, and multiple junctures.

Partially-constructed Single-Use tubing assemblies await finishing by press operators in the new clean room.

An inspector carefully examines a freshly-made molded silicone connection with the use of a light table.

Progress at our Warrington operations is moving very quickly, and we anticipate being able to triple our extrusion capacity of AdvantaFlex® TPE tubing and AdvantaSil® silicone tubing and reinforced hose there later this year. For questions about our renovation projects, contact us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| EQUIPMENT IS MOVED IN AT SOUTHAMPTON August 24, 2021 |

| SOUTHAMPTON FACILITY — Construction, trim work, and utility hookups are finished in the clean room expansion project at our headquarters. The undertaking, which began in April of this year, was fast-tracked so that we could progress toward increased capacity for manufacturing molded components and Single-Use tubing assemblies.

Pictured above is third-party testing of the room's HEPA filtration system. Proper air flow, circulation, and filtration is critical in a clean room environment.

Within a week, mold presses from an adjacent clean room were moved into the space, and members of the company's Engineering and Maintenance teams began setting up the equipment.

Here, technicians fine tune the machinery for peak performance. Press operators will soon be manufacturing Single-Use molded connections in the new space.

If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| CLEAN ROOM WALLS AND FLOORS ARE INSTALLED AT OUR WARRINGTON, PA BUILDING August 17, 2021 |

| WARRINGTON FACILITY — After months of behind-the-scenes work involving HVAC, fluid handling systems, electrical service, and wall studs, clean room construction has begun.

Pictured above is a room where tubing will be manufactured. Clean room walls are up, as well as lighting and hook-ups for ventilation service. The floor has been prepared for its finish layer.

Here's the same room with its flooring and baseboards installed.

The clean room's outer walls await covering. Swift progress with room construction is being made in other areas of the building.

Vats of glycol, a coolant that will be used at the facility, are in storage in the building's warehouse area.

If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| NEARING THE FINISH LINE FOR OUR SOUTHAMPTON, PA, EXPANSION PROJECT August 10, 2021 |

| SOUTHAMPTON FACILITY — Renovations are quickly wrapping up at our headquarters. The 3,000 sq. ft. space, which will be used for AdvantaFlex® molding and assembly, is nearly finished and ready for testing, validation, and equipment.

The floor is cleaned, sanded, and prepped for sealing and a new surface.

And, voila, two days later, a new floor.

Lighting is installed.

The floor is covered for protection as utility hookups for several molding stations are put in place and ceiling tiles begin to go up.

Clean room walls are trimmed out as the project nears completion.

If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| WAREHOUSE, OFFICE, & MORE PREPARATIONS AT WARRINGTON, PA August 03, 2021 |

| WARRINGTON FACILITY — Now that the floors in our 90,000 sq ft facility have been sealed, more construction and installation can proceed.

Above, glycol lines are connected to systems that will help transfer the coolant where it's needed within the building. The glycol is cooled by chillers located outside of the building.

A supervisor's office gets drywall, windows, doors, and paint.

Storage racks and shelves are assembled in the warehouse portion of the facility. These will hold raw silicone and AdvantaFlex® TPE materials to be manufactured into tubing and reinforced hose. They'll also be used to store finished products ready for shipment.

If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| UTILITY INSTALLATION ADVANCES AT OUR SOUTHAMPTON, PA FACILITY July 27, 2021 |

SOUTHAMPTON FACILITY — Electrical wiring, communication cables, and air intakes and ventilation are advancing at our company headquarters. Following testing and validation, the renovated area, which consists of over 3,000 sq. ft., will house injection mold presses and equipment for the assembly, packaging, and inspection of AdvantaFlex® TPE tubing assemblies.

Units for controlling air compression and exchanges are installed in the area's mezzanine.

Framework for a drop ceiling is put into place below the ductwork.

Outer wall panels are in place as work progresses toward the building of clean rooms.

Ceiling tiles and additional wall panels await installation.

If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| LOTS OF RENOVATION PROGRESS AT OUR WARRINGTON, PA FACILITY July 20, 2021 |

WARRINGTON FACILITY — Progress is being made inside and outside, on floors and on ceilings, and behind the scenes and right in front of our eyes. Take a look:

Drywall has been installed in many areas of the building that will house offices for production and quality control supervisors.

These large pipes will transport cooling fluids from the chillers located outdoors to equipment inside.

Concrete floors were washed and sanded.

Floors were then sealed to keep dirt and dust to a minimum.

The sealed floors help reflect illumination from newly-installed, bright, energy-efficient lighting.

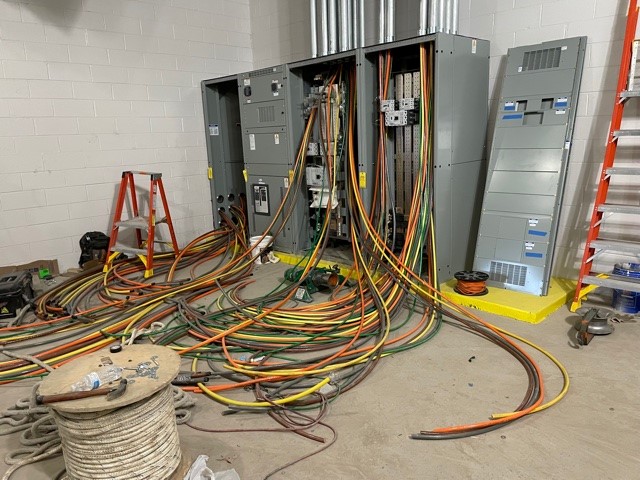

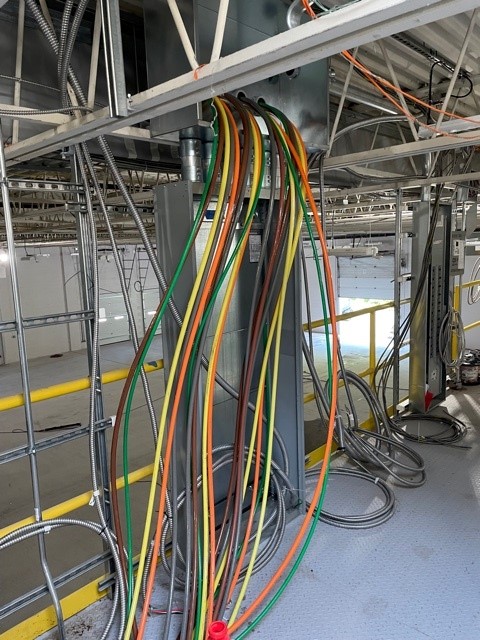

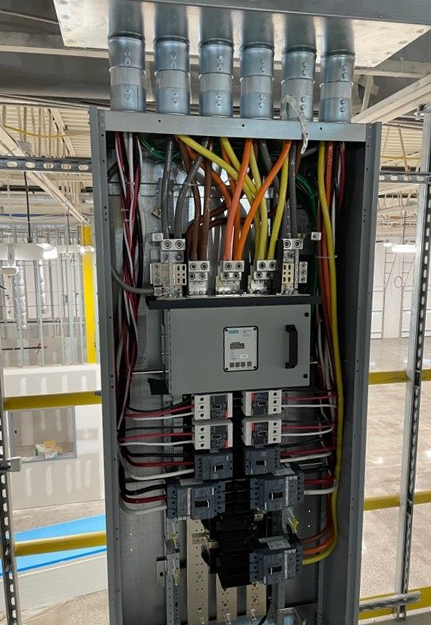

Miles of electrical wires and cables all needed to be positioned in the right areas.

For example, the cables pulled to this box in the mezzanine...

End up organized like this!

These cabinets house air compressors and air control equipment.

If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| CONSTRUCTION SPEEDS UP AT SOUTHAMPTON, PA July 06, 2021 |

| SOUTHAMPTON FACILITY — We're renovating a 3,100 square foot area at our Southampton, PA, headquarters for more space to manufacture AdvantaFlex® Single-Use tubing assemblies. Construction is ahead of schedule, and the installation of electrical and HVAC systems are approaching completion.

It takes a lot of ductwork to provide sufficient air exchanges in an ISO clean room.

Various duct shapes form a complex system for air intake and exhaust.

A high speed roll up door will operate in this newly-built wall.

The installation of clean room wall panels is underway.

If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| CONSTRUCTION MOVES ALONG AT OUR WARRINGTON, PA FACILITY June 30, 2021 |

| WARRINGTON FACILITY — Ductwork, ductwork and more ductwork. And duct work. That's been a focus at our Warrington facility for many weeks now. There's a lot of planning and drawings involved with getting all the service components – air intake and exhaust, heating and cooling, electric supply – in the right places.

It's hard to tell from this photo which ducts will handle which jobs, but it will all make perfect sense as clean room construction progresses. The ductwork appears to cover the entire ceiling.

Although the mezzanine has been constructed, a lot of work at ceiling level must be conducted using scissor lifts.

Work is moving along in other parts of the 90,000 square foot building. Here, wall studs for offices have been erected.

Outside projects are happening, too. Township ordinances required the planting of trees and shrubs as visual and sound barriers to nearby residential areas.

Another ordinance involving decibel levels requires a wall surrounding our outdoor chilling systems, which produce noise from their compressors and fans. The wall is under construction.

If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| CLEAN ROOM RENOVATION CONTINUES AT OUR HEADQUARTERS IN SOUTHAMPTON, PA June 15, 2021 |

| SOUTHAMPTON HEADQUARTERS — NewAge Industries-AdvantaPure is in the midst of two renovations, one at our Southampton, PA, headquarters and another at our Warrington facility.

Demolition work in Southampton began in April 2021 with the removal of a few existing walls and the relocation of employee lockers. The space, consisting of 3,100 square feet, is being refurbished to accommodate more capacity for molding and the manufacture of tubing assemblies made from AdvantaFlex biopharmaceutical grade TPE (thermoplastic elastomer). The area will be certified to ISO 7 standards.

Existing walls are deconstructed to prepare for the renovations.

Portions of the concrete floor are excavated and then reinforced to bear the weight of steel studs that will be installed.

New beams are set to support the roof and the air handling equipment needed for the new clean rooms.

The area’s new mezzanine ties into the that of the existing 20,000 square feet of clean rooms.

Electrical inspections will occur soon, followed by the installation of clean room wall panels and high speed roll up doors. Air ducts have arrived and will be set into place and connected shortly. Construction is anticipated to be completed near the end of next month. If you have questions about our renovations, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| PREPARING FOR DRYWALL, POWERING CLEAN ROOMS, AND RENOVATING WAREHOUSE SPACE May 25, 2021 |

Much of the floor space at our expansion facility is filled with supplies like steel wall studs, drywall, electrical conduit, and boxes of fasteners, as well as high reach trucks that are needed for work at ceiling level. It's all in preparation for clean rooms that will house silicone and TPE extrusion equipment and allow us to make more of this tubing used in vaccine development and production.

More wall studs have been erected as we prep for drywall installation.

Electricians have been busy running electrical wire and conduit from its supply source to the mezzanine. From there, electricity will be supplied to the clean rooms and other areas of the building.

Warehouse space for raw material and finished product storage will have new lighting, a refurbished ceiling, refinished floors, and a thorough paint job.

Much of the extrusion equipment that will be installed in the clean rooms was ordered months ago and is ready and waiting at our Southampton, PA, headquarters. This means that when the building renovations are completed and the new spaces are validated, we'll be ready and able to make additional silicone and TPE tubing quickly. If you have questions about our renovation plans, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| TEAM MEMBERS AND CONSTRUCTION WORKERS RECEIVE VACCINATIONS May 11, 2021 |

| Pennsylvania, where NewAge Industries is located, had tiered COVID-19 vaccination eligibility guidelines, so while many of our team members were busy making tubing and Single-Use molded assemblies for vaccine development and production, they themselves were not yet eligible to receive the vaccine. Thankfully that changed, and all team members were eligible for and offered the COVID-19 vaccine.

More than half of the company's employee-owners took advantage of the opportunity to get vaccinated while at work. Most other team members received shots on their own through vaccination programs at county-run sites, pharmacies, or other healthcare organizations.

Workers who are busy renovating our expansion facility had also been waiting for their turns at getting shots. NewAge made arrangements with Horsham Square Pharmacy, the same pharmacy that vaccinated team members at our Southampton headquarters, to visit our additional building and offer the COVID-19 vaccine to the folks there. These people are working hard to get the facility up and running as quickly as possible, which will allow us to manufacture more silicone and TPE tubing. Being vaccinated helps ensure that we can continue to make the vital tubing that's being used to make more doses available.

|

| BUILDING WALLS AND DEVELOPING EFFICIENT PRODUCT FLOW May 04, 2021 |

As walls for new clean rooms begin to go up, other walls had sections removed. When completed, the clean rooms will house extrusion equipment for manufacturing AdvantaSil® silicone tubing and AdvantaFlex® thermoplastic elastomer (TPE) tubing, both used in the development and production of COVID-19 vaccines. Substantial progress has also been made for the air handling and chiller systems.

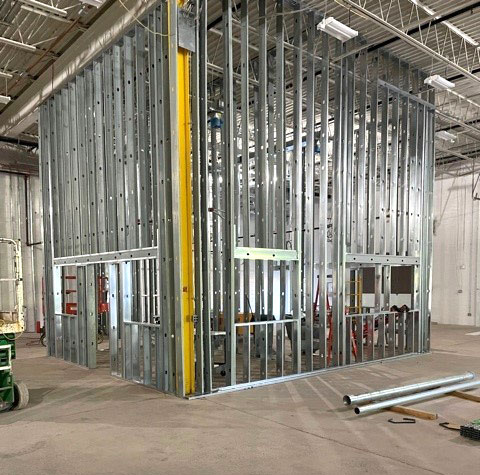

Steel wall studs are being put into place beneath the mezzanine, where the new clean rooms will be housed. Steel is used for framing instead of wood for several reasons. It’s stronger, will not warp, does not attract insects, emits no VOCs, and will not rot.

Additional docks for receiving raw material orders and shipping finished products are being installed. Sections of an existing wall had to first be removed, and existing flooring had to be excavated for new dock plates.

Ducts for moving the large amount of air exchanges necessary in a clean room are being moved into position and connected to each other.

Outside, preparations for the placement of chilling systems were completed, and the large chillers were set in place by crane. Exterior walls received a fresh coat of crisp, white paint.

As we move ahead, ceilings, walls and floors will be installed within the clean room areas, along with electrical outlets and lighting, plumbing, and ventilation. If you have questions about our renovation plans, our staff is available. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|

| RENOVATION PROGRESS CONTINUES April 13, 2021 |

Work continues at a rapid pace at our Warrington, PA, facility. Contractors are installing utility lines and equipment involving electrical service, water, glycol and air.

Pipes for a new sprinkler system were put into place in the ceiling.

Also into the rafters went several large beams to help support supply and return lines for glycol, a chemical used in our manufacturing process's heat exchangers and cooling systems. The lines will transfer glycol back and forth from chilling equipment that will operate on the outside of the building.

Equipment to handle clean room air exchanges was installed on the mezzanine.

And air duct installation has begun.

Work is also being done on sections of the building's concrete floor to ensure that it will support the weight of the equipment that will be placed there (tubing extruders are heavy!). Electrical boxes are being installed, new headers for dock doors are being cut into the walls, and the outside of the facility is getting a fresh coat of paint. If you have questions about our renovation plans, our staff is available. Call us at 215-526-2300 or contact us by e-mail at info@verigenics.com.

|

| RENOVATION PROGRESS CONTINUES March 22, 2021 |

More progress is being made at our additional facility in Warrington, PA, just a few miles from our headquarters.

Following the construction of support beams and floor joists, mezzanine flooring was installed. A stairway allows for easy access to the upper floor, and protective guard rails ensure that contractors stay safe from falls while they're working. Trenches were dug in the building's concrete floor in preparation for plumbing lines and service.

It may not look like it now, but this space will house several clean rooms. We'll be manufacturing AdvantaFlex® TPE tubing and AdvantaSil® silicone tubing and braid reinforced hose at the building, which was purchased last year for the purpose of expanding our manufacturing capabilities. Expansion plans had been in process since 2019 before the right facility – the right size, location and condition – was found.

Work is being done outside, too, where foundations for chillers (large pieces of machinery that chill glycol for the clean rooms) are under construction.

Since the COVID-19 pandemic hit over a year ago and demand for our products increased, it has become even more urgent to make things progress at a steady pace. We're moving quickly and safely and hope to begin installing manufacturing equipment within a few months. If you have questions about our renovation plans, our staff is available to address your inquiries and concerns. Call us at 215-526-2300 or contact us by e-mail at info@verigenics.com.

|

| SPEEDING UP OUR RENOVATIONS February 26, 2021 |

As an Operation Warp Speed (OWS) participant, renovations at both our headquarters in Southampton, PA, and our additional manufacturing site in Warrington, PA, are moving full speed ahead. Demolition phases are completed and construction is underway. Both buildings will house new clean rooms. The space at Southampton will be used for AdvantaPure® silicone molding and Single-Use tubing assemblies, while Warrington will accommodate the manufacture of silicone tubing and braid reinforced hose, as well as AdvantaFlex® biopharmaceutical grade TPE tubing.

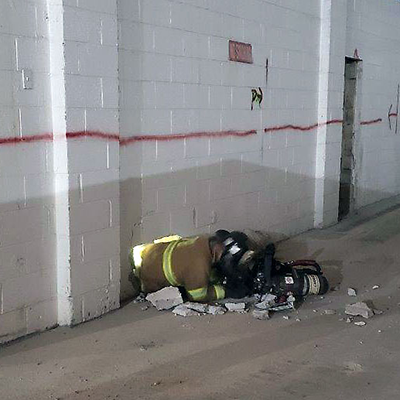

Before we disassembled an old office area at the Warrington facility, we invited the local fire department to tour the building and use the space for drills. The department's volunteer fire fighters performed several mock rescues and practiced breaking through a cinderblock wall to form an escape route. We were happy to provide this opportunity to the men and women who volunteer to protect our communities.

Support beams for a clean room mezzanine area are now in place at Warrington, and the placement of utility lines will soon begin. Walls, ceilings, and floors will follow.

Our contractors are working quickly yet, of course, safely, and progress is made every day. The teams understand the importance of the products that will be manufactured in these renovated sites as much as we do – COVID-19 vaccines are made in processes that use our tubing and Single-Use assemblies. If you have questions about our renovation plans or how OWS may affect your orders, our staff is available. Call us at 215-526-2300 or contact us by e-mail at info@verigenics.com.

|

| WORKING TOWARD INCREASED MANUFACTURING CAPACITY February 09, 2021 |

| It's a fact: The COVID-19 virus has, in one way or another, affected everyone in the world. Even in the few South Pacific island countries with no reported cases, life has changed. Borders are closed and economies are stalled.

NewAge's role in the battle against this relentless virus has necessitated adjustments regarding how we conduct business. Many team members not involved with manufacturing, packaging, inspecting, and shipping our silicone, TPE, and plastic tubing products are working remotely. Those who are here are, of course, wearing masks, social distancing, embracing extra cleaning procedures, and keeping sanitary conditions top of mind. All team members are periodically tested for the virus, and many are now on waiting lists for vaccination appointments. We are fully committed to increasing our manufacturing capacities and improving lead times. Plans have been underway since last year and include:

NewAge is investing $20 million into the two renovation projects and continuing to onboard more employees to fill the new jobs being created. We are continuing our participation in Operation Warp Speed (OWS), a government mandated program initiated to accelerate the development, manufacture, and distribution of COVID-19 vaccines. If you have questions about how our plans or OWS may affect your orders, our staff is available and ready to help. Call us at 215-526-2180 or contact us by e-mail at info@verigenics.com.

|